Why spend thousands on a laser cutter/engraver when you can spend as little as $350 shipped to your door? Sure it’s not as nice as those fancy domestic machines, but the plucky K40 is the little laser that can. Just head on down to Al’s Laser Emporium and pick one up. Yes, it sounds like a used car dealership ad, but how far is it from the truth? Read on to find out!

Laser cutting and engraving machines have been around for decades. Much like 3D printers, they were originally impossibly expensive for someone working at home. The closest you could get to a hobbyist laser was Epilog laser, which would still cost somewhere between $10,000 and $20,000 for a small laser system. A few companies made a go with the Epilog and did quite well – notably Adafruit used to offer laptop laser engraving services.

Over the last decade or so things have changed. China got involved, and suddenly there were cheap lasers on the market. Currently, there are several low-cost laser models available in various power levels. The most popular is the smallest – a 40-watt model, dubbed the K40. There are numerous manufacturers and there have been many versions over the years. They all look about the same though: A blue sheet metal box with the laser tube mounted along the back. The cutting compartment is on the left and the electronics are on the right. Earlier versions came with Moshidraw software and a parallel interface.

Over the last decade or so things have changed. China got involved, and suddenly there were cheap lasers on the market. Currently, there are several low-cost laser models available in various power levels. The most popular is the smallest – a 40-watt model, dubbed the K40. There are numerous manufacturers and there have been many versions over the years. They all look about the same though: A blue sheet metal box with the laser tube mounted along the back. The cutting compartment is on the left and the electronics are on the right. Earlier versions came with Moshidraw software and a parallel interface.

The K40 mechanics haven’t changed very much, but the electronics have been updated to USB with modern stepper drivers. Make no mistake, these are not “quality” machines. They are built down to a cost. Interlock switches are non-existent. Overheat protection for the tube is your problem. Low cooling water flow alarm? Nope, better keep an eye on that yourself. The cutting bed looks like a mixture of an afterthought and parts someone found in the spares bin. The exhaust duct is routed 3 inches into the cutting area. In other words, these are the perfect machines for a hacker.

I’ve been watching the K40 and similar machines on eBay for years. Originally these machines were shipped from China. It was a crapshoot if a large heavy gas filled glass tube would survive the trip halfway around the world. Now, many of the machines are shipping from California and other ports within the lower 48 states. I’m guessing the machines are shipped to a warehouse here in the USA, tested, then the good units are sent on to customers.

I’ve been watching the K40 and similar machines on eBay for years. Originally these machines were shipped from China. It was a crapshoot if a large heavy gas filled glass tube would survive the trip halfway around the world. Now, many of the machines are shipping from California and other ports within the lower 48 states. I’m guessing the machines are shipped to a warehouse here in the USA, tested, then the good units are sent on to customers.

With all this in mind, I finally decided to jump in and get a K40 laser. My first problem was deciding which laser to buy. eBay and Alibaba are riddled with auctions from sellers with different versions of the K40. Everyone says they’re newer and better than the rest. Some boast different accessory packages, and things like air assist – but also cost more. There is enough information to throw even the most seasoned eBayer into analysis paralysis mode.

In the end, I decided to go with one of the cheaper (but not the cheapest) lasers with a digital front panel display. My model also came with a temperature readout for the cooling water, and wheels – for those who like to roll their benchtop lasers around.

I clicked the “buy it now” button and started waiting. The machine in its 62 lb crate would take about a week to ship from the west coast. That gave me plenty of time to order some safety equipment.

Laser Safety

While the K40 may be cheap, I didn’t want to skimp on safety equipment. There are many vendors for laser safe goggles online. There are plenty of them available from China, but I really didn’t want to risk my eyes to a company I had never heard of. I did some checking around and ended up ordering a pair manufactured by Honeywell. Amazon had them available on Prime, so they got to me before the K40 itself. Whichever pair you order, make sure they are rated for CO2 lasers. There are many types of lasers out there, and goggles meant to protect you from a UV medical laser won’t help much at all when it comes to an IR laser like the one in the K40. IR safe glasses will be clear, or nearly so. But don’t mistake them for bog standard safety glasses. These are specially made materials which will help keep you safe from the invisible blindness beam your K40 puts out when your other safety measures fail.

Lasers burn things, and it is unfortunately common for those things to catch fire inside the laser. I’m keeping a large ABC dry powder fire extinguisher near the printer. However, that’s only a stopgap. If you’ve ever had to use a powder extinguisher, you know how messy they are. To try to keep the K40 and the rest of my lab safe, I’m planning to invest in a gas extinguisher of some type. Either CO2 or Halotron, depending on which is safer for use in a basement room.

While I never plan to leave the laser running unattended, I also have smoke detectors in my lab. Finally, I added a carbon monoxide detector to make sure the K40 doesn’t fill the room with a silent killer.

Unboxing

Hackaday doesn’t do unboxing videos, but the impression I got while unpacking the K40 was that it is big – bigger than one would imagine from the photos. My machine measured 32″ wide x 19.75″ deep x 10.25″ high. Thankfully I had workbench space right near a window that made a perfect home.

Cooling

The K40 laser is water cooled. All the lasers include a coolant pump as one of the accessories. The pump I received is a wonder of cost reduction. It’s an aquarium or pond pump, with a magnetically coupled impeller. I was concerned when after use I saw water dripping out of the pump down the 120 V power cord. It turns out the back cover of the pump isn’t even sealed. It doesn’t need to be. The motor stator and coils are potted in black epoxy. As long as that potting compound is in place, nothing can get to the motor. It does seem to work well for keeping the cooling water flowing. However, I can’t say I completely trust it with the life of my laser tube. A mod may be in the future for this system.

The K40 laser is water cooled. All the lasers include a coolant pump as one of the accessories. The pump I received is a wonder of cost reduction. It’s an aquarium or pond pump, with a magnetically coupled impeller. I was concerned when after use I saw water dripping out of the pump down the 120 V power cord. It turns out the back cover of the pump isn’t even sealed. It doesn’t need to be. The motor stator and coils are potted in black epoxy. As long as that potting compound is in place, nothing can get to the motor. It does seem to work well for keeping the cooling water flowing. However, I can’t say I completely trust it with the life of my laser tube. A mod may be in the future for this system.

For coolant, I’m using distilled water. My reservoir for these early tests is a simple shoebox-sized plastic container. It holds a gallon of water and keeps the pump submerged. If the laser isn’t going to be used for a few days, I dump the water and empty the tube by blowing into the inlet line.

Exhaust

Cutting things with a laser will produce smoke and fumes; that’s a given. The K40 comes with an exhaust fan which is rather anemic, to say the least. It’s literally a bathroom exhaust fan slapped on the back of the laser. Smoke is pulled through a slot cut in the back of the case and sent up the exhaust hose. I already have a large Dayton fan mounted in the window of my lab. While the unguarded blades are decidedly dangerous, it moves a crazy amount of air. This coupled with the stock exhaust fan was able to keep the smell of burning wood and plastic down to reasonable levels. However, I’ll definitely be upgrading the stock exhaust in the future.

Aligning The Optics

The first step in setting up one of these lasers is arguably the most dangerous: aligning the mirrors. This is why I bought good laser goggles. Working on the laser with the doors off is something you generally don’t want to do since you can’t control where the beam goes.

The first step in setting up one of these lasers is arguably the most dangerous: aligning the mirrors. This is why I bought good laser goggles. Working on the laser with the doors off is something you generally don’t want to do since you can’t control where the beam goes.

Keep the laser safety glasses on at all times, close the door, and make sure no one else walks into the room. My tube was so far out of alignment that the beam exited the case through the open door and made a small scorch mark on the wall behind my workbench. It would not have been good if someone else was standing there.

There are plenty of video tutorials out there for aligning the mirrors on a K40. I found this one to be particularly helpful. The idea is to make sure that the laser dot hits the center of each of the three mirrors in the beam path. Two of the mirrors move on an X-Y table, so it’s important to make sure the beam hits the same spot no matter where they are positioned. I used Post-it notes rather than the painter’s tape many of the tutorials call for. It’s much easier to see the burn mark on the yellow Post-It than on the dark blue tape.

You don’t need a computer for these steps, just keep the stepper motors off and move the table by hand. When it comes time to fire the laser, you just have to tap the test button on the front panel.

You don’t need a computer for these steps, just keep the stepper motors off and move the table by hand. When it comes time to fire the laser, you just have to tap the test button on the front panel.

The first thing to align is the tube itself. My tube was so far out of alignment that the beam wasn’t even hitting the mirror. The tube is held in with two metal spring straps. Rubber rings keep the straps from breaking the glass tube. More rubber acts as shims to align the tube vertically. I removed one of the shims from the left side of the tube and added it to the right. It’s a fiddly procedure since tightening too hard on the screws will break the single most expensive part of the K40 – the laser tube.

I found that even after an alignment, my K40 still wasn’t performing correctly. I cleaned the mirrors and the laser tube with alcohol, but it was no help. Finally, I disassembled the focusing head. That’s where I found my problem. There were bits of metal inside the head from when it was machined. These metal pieces were in the beam path, disrupting it. I took the 45-degree mirror and the focusing lens out, then carefully cleaned the tube. Once everything was re-assembled, my K40 was ready for action.

I found that even after an alignment, my K40 still wasn’t performing correctly. I cleaned the mirrors and the laser tube with alcohol, but it was no help. Finally, I disassembled the focusing head. That’s where I found my problem. There were bits of metal inside the head from when it was machined. These metal pieces were in the beam path, disrupting it. I took the 45-degree mirror and the focusing lens out, then carefully cleaned the tube. Once everything was re-assembled, my K40 was ready for action.

Software

The laser comes with an obviously burned CD and a USB stick. My laptop doesn’t have a CD drive, so I popped in the USB stick and found… nothing. It’s not really a drive, but a dongle to unlock the laser driver software. I had to go and find my USB cd drive before using the K40. Most of the filenames on the disc are in Chinese. Some digging eventually led me to a file for Corel Laser. It’s a copy of Corel Draw with a plugin to drive the K40. The copy of Corel Draw is almost certainly an illegal cracked copy. I got access to a legit base copy from a friend who switched over to Adobe.

In simple terms, CorelLaser gives you a toolbar and can cut or engrave any image loaded into Corel Draw. Cutting and engraving are very different processes though. Cutting is a vector operation. The laser will trace the path of every line in the image. Engraving is a raster affair. The laser will draw the image line by line, left to right and top to bottom. You can also perform both processes on the same design by creating a cut layer and an engraving layer in the software.

I ran into trouble with the software pretty quickly. Whenever I tried to cut, the laser head moved slowly. Changing the movement settings didn’t help. Some digging eventually pointed me to the settings page for CorelLaser. Here I found the “mainboard” setting was wrong. The value has to match the model number silk screened on the laser mainboard. Of course, the mainboard is mounted in such a way that you can’t read the model number, but a quick cell phone photo fixed that problem. My model is 6C6879-LASER-M2. The board firmware is dated 2018-01-08, so the board must have been built sometime after that.

I ran into trouble with the software pretty quickly. Whenever I tried to cut, the laser head moved slowly. Changing the movement settings didn’t help. Some digging eventually pointed me to the settings page for CorelLaser. Here I found the “mainboard” setting was wrong. The value has to match the model number silk screened on the laser mainboard. Of course, the mainboard is mounted in such a way that you can’t read the model number, but a quick cell phone photo fixed that problem. My model is 6C6879-LASER-M2. The board firmware is dated 2018-01-08, so the board must have been built sometime after that.

I expected CorelLaser to be a hot mess. Honestly, it isn’t half bad. It definitely has some maddening quirks, but overall it does what it should – drive the steppers and switch the laser. The top quirk I’ve found is line width. Corel defaults to “hairline” as line width. This is larger than the laser kerf, so CorelLaser interprets it as two parallel paths. Tracing two close paths on with the K40 will make a wide burning mess of whatever you’re trying to cut. The solution is to select everything in your document <Ctrl-A> then hit F12, and change the line width to .001 mm. CorelLaser will then operate as you expect it to.

Which Materials to use (and which to avoid)

What to cut? As with any laser cutter, thought has to be given to the materials being cut. In general, wood is safe to cut, as is paper, cloth, melamine, pressboard, matte board, cork, some rubbers, natural leather, and Corian. Engraving can be performed on materials such as glass, stone, anodized aluminum, steel (with a laser engraving coating) and other materials.

Some plastics should never be cut in a laser cutter. Anything with chlorine – notably PVC and vinyl. Burning PVC results in chlorine gas, which will kill the user, and hydrochloric acid, which will rust your K40 out so bad that your next of kin won’t be able to enjoy it. A simple test for chlorine is the copper wire burnination test, which can be seen in this 10-year-old video from [Adam] and [Zach] at NYC Resistor. ABS plastic is another one to avoid. It tends to melt and is messy to cut. It also releases trace amounts of cyanide gas. If you’re ever unsure about a material, look up on the pages of hackerspaces who have lasers. If they won’t cut it on their laser, you probably shouldn’t either.

Cutting and Engraving

Cutting and engraving are what we’re all here for, right? The fun part of learning the laser is figuring out how to set up the software for different materials. With a laser, you have three variables to play with. Laser power, speed, and the number of passes. Laser power is controlled by the front panel of the K40. It’s either a knob and an inaccurate milliampere meter or a digital control expressed in power percentage. Cutting with more than one pass is messier than just cutting the material once, so save that for when you really need to do it.

Cutting and engraving are what we’re all here for, right? The fun part of learning the laser is figuring out how to set up the software for different materials. With a laser, you have three variables to play with. Laser power, speed, and the number of passes. Laser power is controlled by the front panel of the K40. It’s either a knob and an inaccurate milliampere meter or a digital control expressed in power percentage. Cutting with more than one pass is messier than just cutting the material once, so save that for when you really need to do it.

There are a few guides out there – I’ve found this page to be a good starting point for figuring out which speeds and power levels to run at for a given material. I generally will use the speed from that site, then start at a much lower laser power. Testing on scrap pieces, I’ll keep raising the power until I have a clean cut. If the power is below 50%, I’ll generally stick with it, and not adjust the speed.

You should definitely keep notes of what you use. On my laser, I found a deep engrave on ⅛” acrylic at 50% and 320 mm/s. Cutting ⅛” birch plywood worked best at 25% power and 5 mm/s. Keep in mind that quality control on the K40 is non-existent, and beam focus will matter, so your device may be different from mine. Further, materials such as plywood and acrylic can change from batch to batch depending on moisture content and other variables. Always buy some extra material to use as scrap for dialing in your settings.

You should definitely keep notes of what you use. On my laser, I found a deep engrave on ⅛” acrylic at 50% and 320 mm/s. Cutting ⅛” birch plywood worked best at 25% power and 5 mm/s. Keep in mind that quality control on the K40 is non-existent, and beam focus will matter, so your device may be different from mine. Further, materials such as plywood and acrylic can change from batch to batch depending on moisture content and other variables. Always buy some extra material to use as scrap for dialing in your settings.

Performance

So how good is the K40 in a “bone stock” condition? Pretty damn good actually. I was able to cut ⅛” birch plywood and ⅛” acrylic with one pass at less than 50% power. The parts would literally fall out as each cut complete. This is a laser, so of course, there is some charring of the wood on the edges, but nothing a bit of sandpaper can’t fix. As a torture test, I took the Hackaday logo .svg file loaded it up into CorelLaser, set the line width to .001 mm, and hit go. The K40 dutifully cut out the jolly wrencher, giving me a little puzzle of pieces to try to fit back together.

So how good is the K40 in a “bone stock” condition? Pretty damn good actually. I was able to cut ⅛” birch plywood and ⅛” acrylic with one pass at less than 50% power. The parts would literally fall out as each cut complete. This is a laser, so of course, there is some charring of the wood on the edges, but nothing a bit of sandpaper can’t fix. As a torture test, I took the Hackaday logo .svg file loaded it up into CorelLaser, set the line width to .001 mm, and hit go. The K40 dutifully cut out the jolly wrencher, giving me a little puzzle of pieces to try to fit back together.

Engraving performance was good too – I was able to cut simple black and white images (and text) into wood and acrylic. I can see how this would be perfect for making control panels with labeled lights and switches.

Summary

The K40 is a cheap laser engraver/cutter. However, it is very capable, even when used unmodified. That said, the cutter is a great platform for modification. You can bet I’ll be spending some time adding things like air assist and a better bed to my K40 as well as cutting down that exhaust duct.

The iconic robot helmets of Daft Punk feature prominently as challenging DIY hardware projects in their own right, and the results never disappoint. But [Nathaniel Stepp]’s

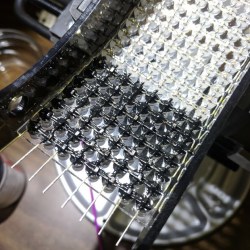

The iconic robot helmets of Daft Punk feature prominently as challenging DIY hardware projects in their own right, and the results never disappoint. But [Nathaniel Stepp]’s  After the whole array was assembled and working, the back of each LED appears to have then been carefully coated in what looks like Plasti-Dip in order to block light, probably to minimize the blinding of the wearer. A small amount of space between each LED allows the eyeballs inside the helmet to see past the light show in the visor.

After the whole array was assembled and working, the back of each LED appears to have then been carefully coated in what looks like Plasti-Dip in order to block light, probably to minimize the blinding of the wearer. A small amount of space between each LED allows the eyeballs inside the helmet to see past the light show in the visor.

However, he didn’t find that out right away. He first experimented with his own techniques, learning that if he fed bricks to his conveyor belt by dropping a batch of them in a line perpendicular to the direction of belt travel then no subsequent separation attempt of his worked. He then turned to

However, he didn’t find that out right away. He first experimented with his own techniques, learning that if he fed bricks to his conveyor belt by dropping a batch of them in a line perpendicular to the direction of belt travel then no subsequent separation attempt of his worked. He then turned to

Over the last decade or so things have changed. China got involved, and suddenly there were cheap lasers on the market. Currently, there are several low-cost laser models available in various power levels. The most popular is the smallest – a 40-watt model, dubbed the K40. There are numerous manufacturers and there have been many versions over the years. They all look about the same though: A blue sheet metal box with the laser tube mounted along the back. The cutting compartment is on the left and the electronics are on the right. Earlier versions came with Moshidraw software and a parallel interface.

Over the last decade or so things have changed. China got involved, and suddenly there were cheap lasers on the market. Currently, there are several low-cost laser models available in various power levels. The most popular is the smallest – a 40-watt model, dubbed the K40. There are numerous manufacturers and there have been many versions over the years. They all look about the same though: A blue sheet metal box with the laser tube mounted along the back. The cutting compartment is on the left and the electronics are on the right. Earlier versions came with Moshidraw software and a parallel interface. I’ve been watching the K40 and similar machines on eBay for years. Originally these machines were shipped from China. It was a crapshoot if a large heavy gas filled glass tube would survive the trip halfway around the world. Now, many of the machines are shipping from California and other ports within the lower 48 states. I’m guessing the machines are shipped to a warehouse here in the USA, tested, then the good units are sent on to customers.

I’ve been watching the K40 and similar machines on eBay for years. Originally these machines were shipped from China. It was a crapshoot if a large heavy gas filled glass tube would survive the trip halfway around the world. Now, many of the machines are shipping from California and other ports within the lower 48 states. I’m guessing the machines are shipped to a warehouse here in the USA, tested, then the good units are sent on to customers. The K40 laser is water cooled. All the lasers include a coolant pump as one of the accessories. The pump I received is a wonder of cost reduction. It’s an aquarium or pond pump, with a magnetically coupled impeller. I was concerned when after use I saw water dripping out of the pump down the 120 V power cord. It turns out the back cover of the pump isn’t even sealed. It doesn’t need to be. The motor stator and coils are potted in black epoxy. As long as that potting compound is in place, nothing can get to the motor. It does seem to work well for keeping the cooling water flowing. However, I can’t say I completely trust it with the life of my laser tube. A mod may be in the future for this system.

The K40 laser is water cooled. All the lasers include a coolant pump as one of the accessories. The pump I received is a wonder of cost reduction. It’s an aquarium or pond pump, with a magnetically coupled impeller. I was concerned when after use I saw water dripping out of the pump down the 120 V power cord. It turns out the back cover of the pump isn’t even sealed. It doesn’t need to be. The motor stator and coils are potted in black epoxy. As long as that potting compound is in place, nothing can get to the motor. It does seem to work well for keeping the cooling water flowing. However, I can’t say I completely trust it with the life of my laser tube. A mod may be in the future for this system. The first step in setting up one of these lasers is arguably the most dangerous: aligning the mirrors. This is why I bought good laser goggles. Working on the laser with the doors off is something you generally don’t want to do since you can’t control where the beam goes.

The first step in setting up one of these lasers is arguably the most dangerous: aligning the mirrors. This is why I bought good laser goggles. Working on the laser with the doors off is something you generally don’t want to do since you can’t control where the beam goes. You don’t need a computer for these steps, just keep the stepper motors off and move the table by hand. When it comes time to fire the laser, you just have to tap the test button on the front panel.

You don’t need a computer for these steps, just keep the stepper motors off and move the table by hand. When it comes time to fire the laser, you just have to tap the test button on the front panel. I found that even after an alignment, my K40 still wasn’t performing correctly. I cleaned the mirrors and the laser tube with alcohol, but it was no help. Finally, I disassembled the focusing head. That’s where I found my problem. There were bits of metal inside the head from when it was machined. These metal pieces were in the beam path, disrupting it. I took the 45-degree mirror and the focusing lens out, then carefully cleaned the tube. Once everything was re-assembled, my K40 was ready for action.

I found that even after an alignment, my K40 still wasn’t performing correctly. I cleaned the mirrors and the laser tube with alcohol, but it was no help. Finally, I disassembled the focusing head. That’s where I found my problem. There were bits of metal inside the head from when it was machined. These metal pieces were in the beam path, disrupting it. I took the 45-degree mirror and the focusing lens out, then carefully cleaned the tube. Once everything was re-assembled, my K40 was ready for action. I ran into trouble with the software pretty quickly. Whenever I tried to cut, the laser head moved slowly. Changing the movement settings didn’t help. Some digging eventually pointed me to the settings page for CorelLaser. Here I found the “mainboard” setting was wrong. The value has to match the model number silk screened on the laser mainboard. Of course, the mainboard is mounted in such a way that you can’t read the model number, but a quick cell phone photo fixed that problem. My model is 6C6879-LASER-M2. The board firmware is dated 2018-01-08, so the board must have been built sometime after that.

I ran into trouble with the software pretty quickly. Whenever I tried to cut, the laser head moved slowly. Changing the movement settings didn’t help. Some digging eventually pointed me to the settings page for CorelLaser. Here I found the “mainboard” setting was wrong. The value has to match the model number silk screened on the laser mainboard. Of course, the mainboard is mounted in such a way that you can’t read the model number, but a quick cell phone photo fixed that problem. My model is 6C6879-LASER-M2. The board firmware is dated 2018-01-08, so the board must have been built sometime after that. Cutting and engraving are what we’re all here for, right? The fun part of learning the laser is figuring out how to set up the software for different materials. With a laser, you have three variables to play with. Laser power, speed, and the number of passes. Laser power is controlled by the front panel of the K40. It’s either a knob and an inaccurate milliampere meter or a digital control expressed in power percentage. Cutting with more than one pass is messier than just cutting the material once, so save that for when you really need to do it.

Cutting and engraving are what we’re all here for, right? The fun part of learning the laser is figuring out how to set up the software for different materials. With a laser, you have three variables to play with. Laser power, speed, and the number of passes. Laser power is controlled by the front panel of the K40. It’s either a knob and an inaccurate milliampere meter or a digital control expressed in power percentage. Cutting with more than one pass is messier than just cutting the material once, so save that for when you really need to do it. You should definitely keep notes of what you use. On my laser, I found a deep engrave on ⅛” acrylic at 50% and 320 mm/s. Cutting ⅛” birch plywood worked best at 25% power and 5 mm/s. Keep in mind that quality control on the K40 is non-existent, and beam focus will matter, so your device may be different from mine. Further, materials such as plywood and acrylic can change from batch to batch depending on moisture content and other variables. Always buy some extra material to use as scrap for dialing in your settings.

You should definitely keep notes of what you use. On my laser, I found a deep engrave on ⅛” acrylic at 50% and 320 mm/s. Cutting ⅛” birch plywood worked best at 25% power and 5 mm/s. Keep in mind that quality control on the K40 is non-existent, and beam focus will matter, so your device may be different from mine. Further, materials such as plywood and acrylic can change from batch to batch depending on moisture content and other variables. Always buy some extra material to use as scrap for dialing in your settings. So how good is the K40 in a “bone stock” condition? Pretty damn good actually. I was able to cut ⅛” birch plywood and ⅛” acrylic with one pass at less than 50% power. The parts would literally fall out as each cut complete. This is a laser, so of course, there is some charring of the wood on the edges, but nothing a bit of sandpaper can’t fix. As a torture test, I took the Hackaday logo .svg file loaded it up into CorelLaser, set the line width to .001 mm, and hit go. The K40 dutifully cut out the jolly wrencher, giving me a little puzzle of pieces to try to fit back together.

So how good is the K40 in a “bone stock” condition? Pretty damn good actually. I was able to cut ⅛” birch plywood and ⅛” acrylic with one pass at less than 50% power. The parts would literally fall out as each cut complete. This is a laser, so of course, there is some charring of the wood on the edges, but nothing a bit of sandpaper can’t fix. As a torture test, I took the Hackaday logo .svg file loaded it up into CorelLaser, set the line width to .001 mm, and hit go. The K40 dutifully cut out the jolly wrencher, giving me a little puzzle of pieces to try to fit back together.